Essential Summer 2025 Maintenance Checklist for Contractor Equipment

Ensuring every piece of your construction equipment is operational during the summer heat is crucial for the safety of your team, timely project completion, and reducing overall costs. But did you know that proper equipment maintenance could also help lower your insurance premiums? If you're a contractor planning for the busy summer of 2025, we've got you covered.

This blog walks you through the most important equipment maintenance practices, offering practical strategies to optimize safety and minimize risks. We’ve even included a checklist to simplify your summer planning.

Why Summer 2025 Demands Special Attention

Summers are getting hotter, and keeping your equipment functional during extreme weather is becoming more challenging. Prolonged periods of elevated heat not only stress equipment but also create new safety risks for employees and subcontractors working on these machines. Malfunctions, breakdowns, or mishaps caused by overheating can lead to delays, injuries, and even insurance claims.

Proactive maintenance isn’t just about preventing breakdowns. It’s about protecting your people, achieving operational efficiency, and strengthening your financial position through reduced risks and insurance optimization.

Summer Challenges for Construction Equipment

When temperatures soar, here's how the summer heat impacts your construction equipment and business operations:

Overheating Machinery: Prolonged usage under direct sunlight can compromise critical systems.

Reduced Lubrication: High heat reduces the effectiveness of grease and oil, leading to increased wear and tear.

Tires Under Pressure: Extreme temperatures can overinflate or weaken tires, risking blowouts.

Employee Safety Risks: Hot surfaces and stressed equipment can become safety hazards for your team.

Staying a step ahead means focusing on seasonal maintenance. Here's how to do it.

Cooling System Maintenance Protocols

Cooling systems are your frontline defense against overheating. To ensure they function efficiently, follow these steps:

Flush the Radiator: Prevent debris build-up and ensure optimal coolant circulation.

Use Summer-Grade Coolant: Opt for coolants designed to withstand high temperatures.

Inspect Belts and Hoses: Heat can cause cracks or leaks. Replace damaged components promptly.

Check Fans and Blowers: Ensure blades are clean and functioning at full capacity.

Specialized System Maintenance Requirements

Some equipment has unique needs during extreme summer conditions. Keep these in mind:

Hydraulic Systems: Check fluid levels and filters frequently, as heat deteriorates hydraulic oil faster.

Electrical Systems: Inspect wiring and connectors for melting risks. Secure any loose connections.

Air Intake Systems: Clean filters regularly to maintain airflow and engine health.

Preventative Maintenance Strategies for Peak Season

Preventative maintenance is the backbone of summer operations. It not only mitigates downtimes but also demonstrates the operational diligence required for optimizing insurance premiums.

Daily Equipment Inspections: Have operators examine machinery for visible wear, leaks, and functionality.

Routine Servicing: Schedule check-ups before the peak work rush. Pay special attention to frequently used equipment.

Operator Training: Use training sessions to educate teams on safe operating practices during high-heat conditions.

Air Filtration and Environmental Protection

Hot and dusty conditions in summer can clog air filters quickly, impacting engine performance and increasing fuel usage. Follow these steps to stay ahead:

Replace or clean air filters every two weeks, depending on site conditions.

Ensure HVAC systems in cabs are functional to prevent operator fatigue.

Use covers and protective equipment when machines are idle to prevent sun damage.

Reduce Insurance Premiums With Outstanding Maintenance

Many contractors don’t realize that insurance companies reward proactive maintenance. Maintaining your equipment reduces risks associated with downtime, accidents, and claims, which can lead to better terms during policy renewals.

Inspection Records: Document all maintenance tasks meticulously. Having a track record lowers your risk profile in the eyes of insurers.

Fleet Management Systems: Implement technology for real-time maintenance alerts and tracking.

Insurer Communication: Share documentation on your maintenance strategies during policy reviews to negotiate better coverage.

Claim Prevention and Approval Strategies

Accidents happen, even with robust maintenance. But there are strategies to prevent potential claims or speed up approvals when incidents occur:

Document Everything: Keep logs for inspections, repairs, and expenses.

Safety Training Records: Proof of staff training shows insurers that your team understands risk.

Incident Reports: Note down any near-miss events and how you resolved them.

Seasonal Transition Planning

Summer doesn’t last forever, and you’ll need to prepare equipment for the next season. Start planning for a seamless transition now:

Inspect heating systems on heavy machinery at the end of summer.

Rotate summer-used equipment to rest and focus maintenance on winter machinery.

Order any spare parts likely to wear down before the next heat season.

Technology Integration and Monitoring

Technology is transforming how contractors maintain their fleets. Using AI-driven systems and telematics helps monitor equipment in real time and provides data-driven insights.

Preventative Alerts: Get notified about impending malfunctions before they escalate.

Energy Efficiency Metrics: Track how heat affects your fuel consumption and system efficiency.

Streamlined Documentation: Use digital platforms to centralize maintenance logs, compliance documentation, and records for easier insurance reviews.

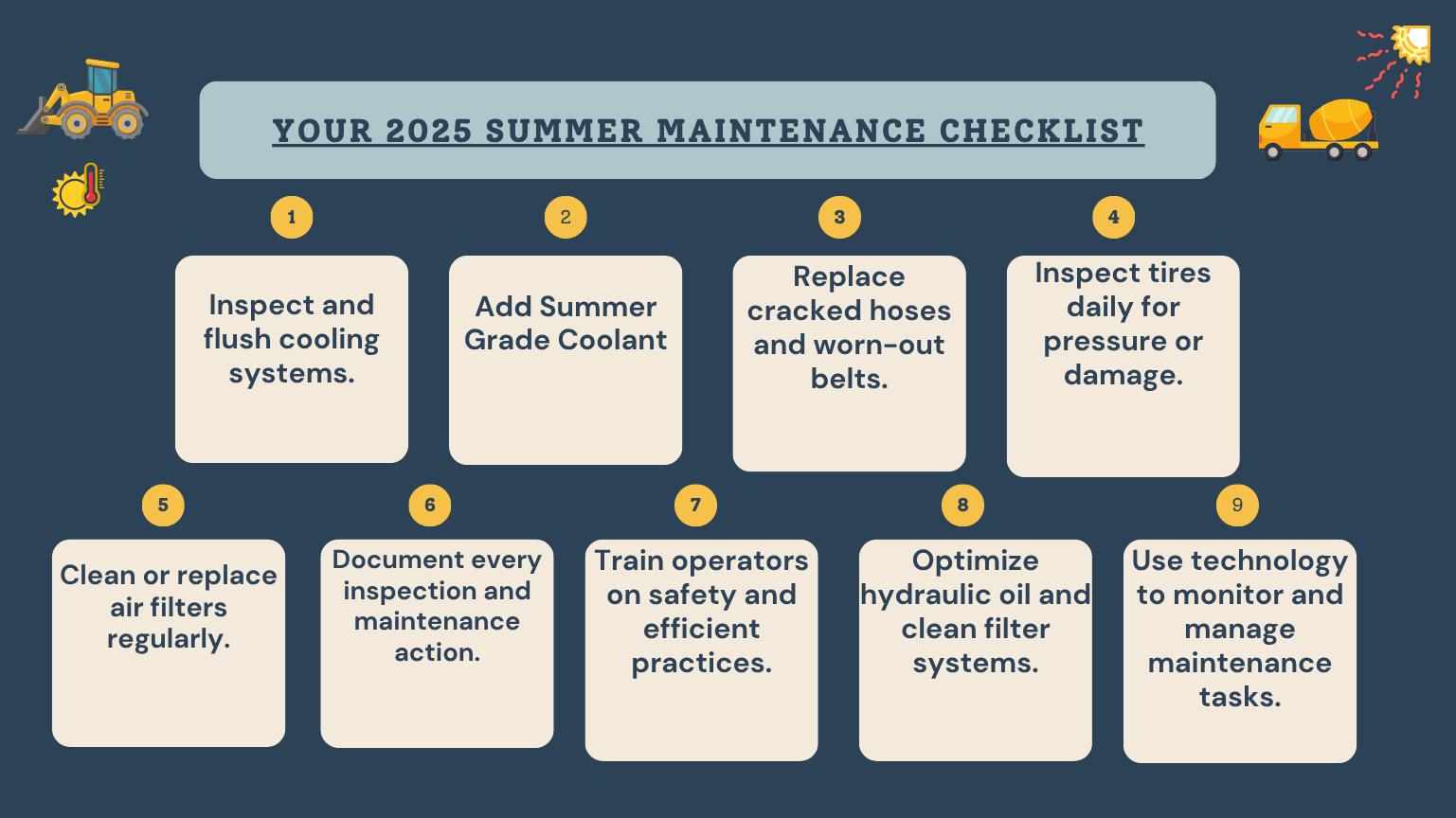

Your 2025 Summer Maintenance Checklist

Here’s a quick checklist to ensure your bases are covered this summer:

Inspect and flush cooling systems.

Add summer-grade coolant.

Replace cracked hoses and worn-out belts.

Inspect tires daily for pressure or damage.

Clean or replace air filters regularly.

Document every inspection and maintenance action.

Train operators on safety and efficient practices.

Optimize hydraulic oil and clean filter systems.

Use technology to monitor and manage maintenance tasks.

Prepare Your Fleet for a Stress-Free Summer

This summer, high-performing equipment is non-negotiable for safely navigating the challenges of the season. By proactively following these maintenance guidelines, you’ll not only enjoy increased operational efficiency but also boost your chances of reducing insurance premiums.

Book a call with me today, and together, we’ll build a tailored insurance plan that sets your business up for long-term success. I’m here to help. Book a call or email me at Bret@BGAgencyins.com.